How APFC Panels Improve Power Factor and Save Energy

When it comes to managing electricity efficiently—especially in industrial and commercial spaces—power factor plays a major role. And one device that helps manage this like a pro is the APFC Panels. If you’ve heard the term but aren’t exactly sure what it means or why it’s important, you’re in the right place.

Let’s break it down.

⚡ First, What Is Power Factor in APFC Panels ?

Before we jump into what are APFC panels is, let’s quickly understand power factor.

Power factor is a measure of how effectively electrical power is being used. It’s the ratio between real power (used to do actual work) and apparent power (total power supplied). It ranges between 0 and 1, and the closer to 1, the better.

A low power factor means you’re drawing more current than necessary—wasting energy, increasing your electricity bill, and putting more stress on your electrical systems.

🧠 So, What Is an Automatic Power Factor Control (APFC Panels)?

An APFC Panels is an electrical control panel that automatically manages and improves the power factor of a facility by switching capacitor banks in or out of the electrical circuit depending on the load conditions.

It continuously monitors the power factor and makes real-time adjustments to maintain it close to unity (1.0).

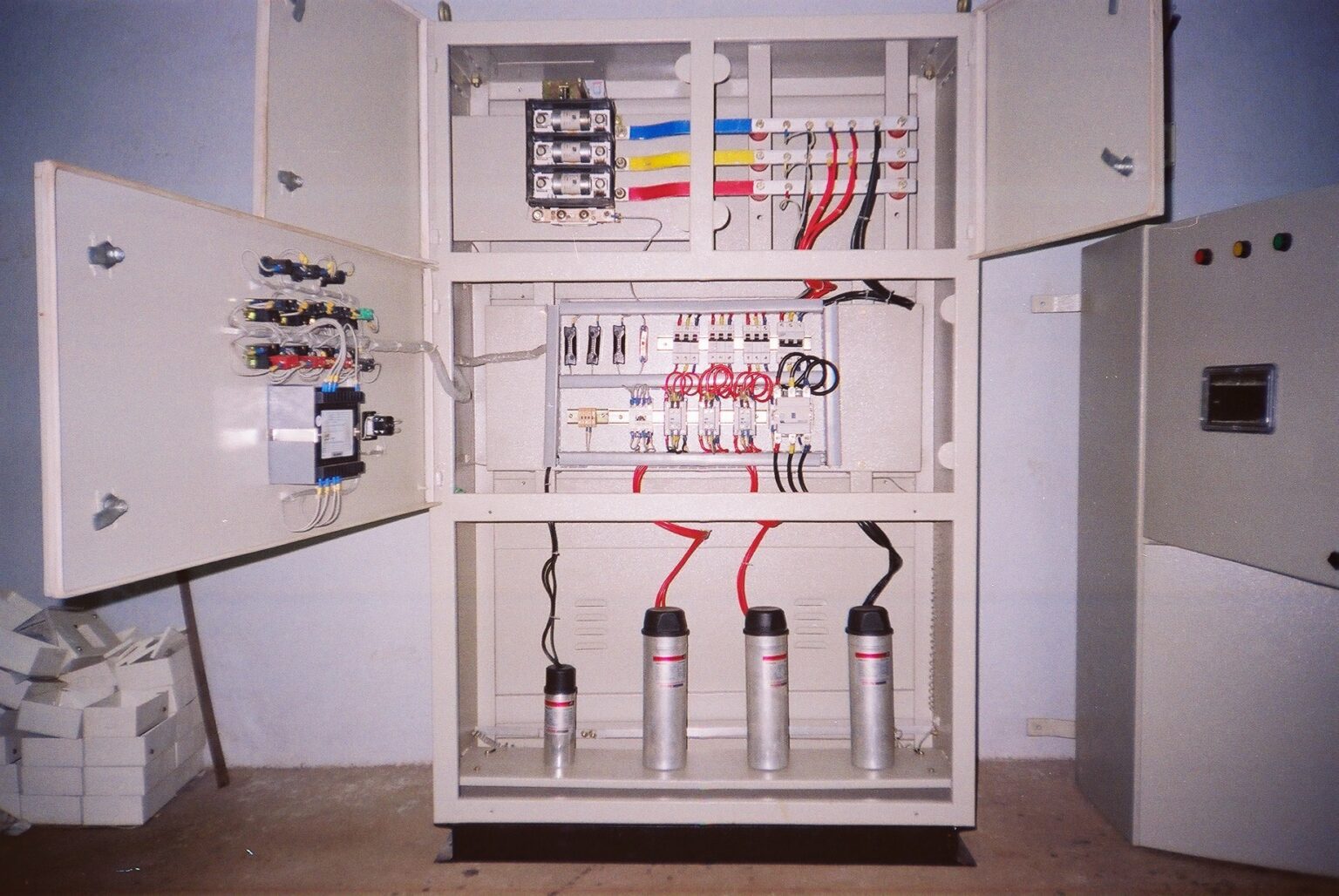

🧩 Key Components of an APFC Panels

Here are some of the essential parts:

Power Factor Controller – The brain of the panel. It detects the power factor and decides how many capacitor steps to turn ON or OFF.

Capacitor Banks – These are the devices that correct the power factor by compensating for the reactive power.

Contactors/Relays – Switches that control the connection of capacitor banks to the system.

MCBs/MCCBs – Circuit breakers that provide protection.

CTs (Current Transformers) – Measure current to feed data into the controller.

Cooling Fans & Indicators – For proper ventilation and easy monitoring.

🛠️ How Does It Work?

Here’s a simple step-by-step of how an APFC panels operates:

The system continuously monitors the electrical load and power factor.

If the power factor drops below a set threshold, the controller activates the required number of capacitor banks.

As the load changes, the APFC panel adjusts by turning capacitors ON or OFF.

This correction helps bring the power factor closer to 1, making the system more efficient.

💰 Why Is It Important?

An APFC panels isn’t just a “nice-to-have”—it delivers real benefits:

✅ Reducing electricity bills by minimizing reactive power penalties.

✅ Improves energy efficiency.

✅ Increases the lifespan of electrical equipment by reducing overheating.

✅ Avoids power losses and voltage drops in the system.

✅ Ensures compliance with power utility standards.

🏭 Where Is It Used?

APFC panels are widely used in:

Manufacturing plants

Shopping malls

Hospitals

Data centers

Commercial complexes

🧾 Final Thoughts

An Automatic Power Factor Control Panel might not be something you think about daily, but its impact on your energy consumption and operational efficiency is huge. Whether you’re managing a factory or a high-rise building, investing in an APFC panels can lead to serious long-term savings and reliability.

They enhance energy efficiency, reduce electricity bills, and minimize power losses by automatically adjusting reactive power. APFC panels are especially beneficial in industrial and commercial settings with fluctuating loads. By ensuring compliance with electricity board regulations and preventing penalties, they offer long-term cost savings.

Their integration into power systems leads to improved voltage stability and extended equipment lifespan. Overall, APFC panels are an essential investment for any facility aiming for energy-efficient and reliable electrical infrastructure.

Still have questions? Drop them in the comments below or reach out—happy to help you make your power cleaner and smarter!