In an era defined by rapid technological advancements and environmental consciousness, electric vehicles (EVs) have emerged as a transformative force in transportation. At the heart of these sleek, silent machines lies their power source: the electric vehicle battery. As interest in EVs surges, so does curiosity about the technology driving them. In this comprehensive guide, we delve deep into the world of electric vehicle batteries, demystifying their workings, exploring their types, and unraveling the science behind their efficiency and sustainability. Join us as we navigate through the complexities to shed light on the future of automotive power.

Understanding Electric Vehicle Battery

Electric vehicle batteries serve as the primary energy storage unit, powering the vehicle’s electric motor and all its ancillary systems. Unlike traditional gasoline-powered cars, which burn fossil fuels to generate energy, EV batteries store electrical energy that is used to propel the vehicle.

Battery Components

- Anode: The negative electrode where electrical current flows into the battery during charging.

- Cathode: The positive electrode where electrical current flows out of the battery during charging.

- Electrolyte: A chemical medium that allows ions to move between the anode and cathode while electrically insulating them from each other.

Working Principle

Charging: When an electric vehicle is plugged into a charging station, electricity flows from the grid into the battery pack. During this process:

- Anode: Lithium ions are extracted from the anode material (typically graphite) and move through the electrolyte towards the cathode.

- Cathode: Simultaneously, lithium ions move into the cathode material (usually a metal oxide like lithium cobalt oxide or lithium iron phosphate), where they are stored.

Discharging: When the vehicle is in use, the stored chemical energy is converted back into electrical energy to power the electric motor and other vehicle systems:

- Anode: Lithium ions return from the cathode through the electrolyte to the anode.

- Cathode: Lithium ions release electrons, which flow through an external circuit to power the electric motor and perform work.

Electric Motor Operation: The electrical current provided by the battery powers the electric motor, generating rotational motion that drives the vehicle’s wheels.

Types of Electric Vehicle Batteries

Lithium-Ion Batteries: These are the most common type of batteries used in electric vehicles today. They offer high energy density, which translates to longer driving ranges per charge. Lithium-ion batteries come in several variations, including:

- NMC (Nickel Manganese Cobalt): Balances energy density, power output, and longevity.

- NCA (Nickel Cobalt Aluminum): Provides high energy density and power output, often used in high-performance EVs.

- LFP (Lithium Iron Phosphate): Known for their safety and longevity, although with slightly lower energy density.

Solid-State Batteries: These are the next frontier in battery technology. Solid-state batteries promise higher energy densities, faster charging times, and improved safety due to their solid electrolyte material. While still in the early stages of commercialization, they hold the potential to further enhance EV performance and reliability.

Other Types: Historically, Nickel-Metal Hydride (NiMH) batteries were used in earlier hybrid vehicles but have largely been surpassed by lithium-ion technology in pure EVs.

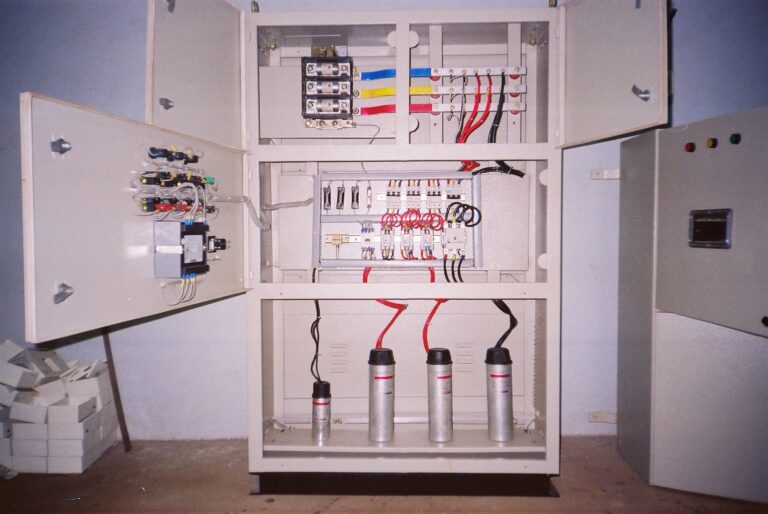

Battery Management Systems

To optimize performance and ensure longevity, electric vehicles are equipped with sophisticated Battery Management Systems (BMS). These systems monitor and control various parameters such as temperature, voltage, and state of charge. By actively managing these factors, BMS enhances battery efficiency and safety.

Future Trends

Looking ahead, several trends are shaping the future of electric vehicle batteries:

- Improved Energy Density: Continual advancements aim to increase the energy density of batteries, enabling longer driving ranges and better performance.

- Enhanced Charging Infrastructure: Expansion of fast-charging networks and advancements in charging technology will reduce charging times, making EVs more convenient for consumers.

- Cost Reductions: Economies of scale and technological innovations are driving down battery costs, making electric vehicles more accessible to a broader range of consumers.

- Material Innovations: Research into alternative materials and manufacturing techniques seeks to improve battery performance, safety, and sustainability.

Conclusion

Electric vehicle batteries represent a crucial technological advancement in transportation, offering clean, efficient, and increasingly affordable alternatives to traditional internal combustion engines. Understanding the working principles of EV batteries highlights their importance in reducing greenhouse gas emissions and promoting sustainable mobility solutions worldwide. As technology continues to evolve, advancements in battery chemistry, manufacturing processes, and recycling capabilities will further enhance the efficiency, affordability, and environmental benefits of electric vehicles.