How MCC Panels Drive Industrial Automation Success

In the rapidly evolving world of industrial automation, efficiency, reliability, and safety are more crucial than ever. As industries embrace smarter manufacturing processes, the Motor Control Center (MCC) panel has become a key component in streamlining operations and managing complex motor-driven systems. MCC panels play a central role in improving industrial automation by offering centralized control, operational efficiency, system protection, and scalability.

What is an MCC Panel?

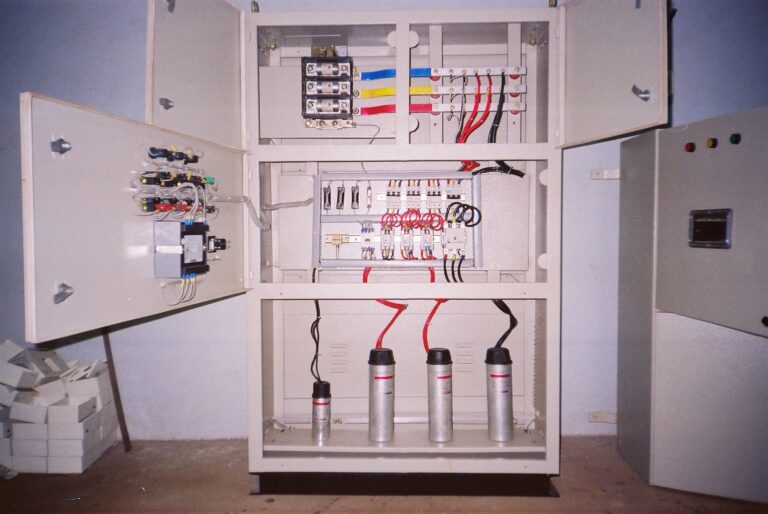

A Motor Control Center (MCC) panel is an assembly that houses multiple motor starters in a central location. These starters include components such as circuit breakers, fuses, overload relays, and contactors. The MCC panel is designed to control several electric motors from a single, centralized location, making it easier to manage and monitor motor operations across an industrial facility.

Centralized Control and Monitoring

One of the biggest advantages of MCC panels in industrial automation is centralized control. Instead of having to manage motors individually, operators can monitor and control multiple motors from one point. This centralization reduces human error, improves workflow, and allows for quicker diagnostics and troubleshooting. Integrated with Programmable Logic Controllers (PLCs) and Human Machine Interfaces (HMIs), MCC panels become part of a broader automation architecture that provides real-time data and analytics, improving decision-making.

Enhanced Safety and Protection

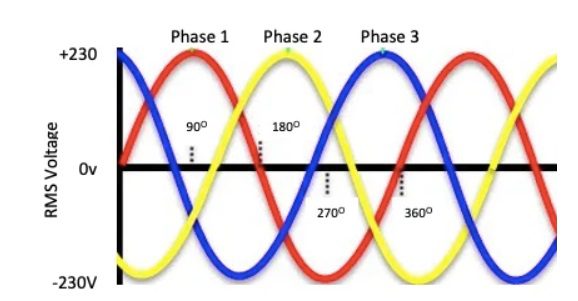

Industrial environments are prone to electrical faults, mechanical failures, and operational hazards. MCC panels offer built-in protection features that safeguard both the equipment and personnel. These include short-circuit protection, overload relays, and phase failure protection. MCCs also enable the isolation of faulty sections, allowing maintenance without shutting down the entire system. This modular design not only ensures operational continuity but also significantly enhances workplace safety.

Operational Efficiency

With automation, consistency and speed are vital. MCC panels contribute to operational efficiency by automating motor start/stop sequences, managing variable speeds, and ensuring smooth operation of production lines. When integrated with Variable Frequency Drives (VFDs) and Soft Starters, MCC panels help reduce energy consumption and mechanical stress on motors, leading to lower maintenance costs and prolonged equipment life. These factors are essential in achieving lean manufacturing goals and minimizing downtime.

Scalability and Flexibility

As industries grow and adapt to changing demands, having a flexible automation system is crucial. MCC panels are designed with modularity in mind, allowing easy expansion or reconfiguration. New motor units can be added without significant downtime or disruption to existing operations. This scalability makes MCC panels future-proof, accommodating both immediate and long-term automation needs.

Integration with Smart Systems

The rise of Industry 4.0 has pushed the boundaries of industrial automation. Modern MCC panels are no longer just switchboards—they’re intelligent systems that can be integrated with Industrial Internet of Things (IIoT) devices, SCADA systems, and cloud-based platforms. These integrations provide remote monitoring, predictive maintenance, and energy management solutions, driving a data-driven approach to automation. With real-time alerts and performance insights, industries can proactively address issues and optimize production processes.

Cost-Effectiveness

While the initial investment in MCC panels may seem significant, the long-term benefits far outweigh the costs. Reduced energy consumption, fewer breakdowns, lower labor costs due to automation, and minimized downtime all contribute to a better return on investment. Moreover, centralized diagnostics reduce the need for frequent manual inspections, helping businesses save time and resources.

Conclusion

MCC panels are more than just control boxes—they are foundational elements in modern industrial automation. By offering centralized control, enhancing safety, improving efficiency, and enabling smart integrations, MCC panels empower industries to meet high performance and productivity standards. As automation continues to reshape the industrial landscape, investing in a robust MCC infrastructure is a step toward a smarter, safer, and more scalable future.